The grinding mill liners are integral parts of a grinding mill. Liners are the materials which are used on the inner surface of the grinding shell to provide the necessary strength and resistance. Lining is used on all surfaces with which ...

The grinding in a laboratory ball mill, on the other hand, is discontinuous. The clinkers and agent are sealed in the mill until ground to proper size, thus much better distribution of dry material is effected. The more perfect ...

concrete workability mill temperature required cement temperature out of the mill . Concrete temperature ... the desired workability for the fresh concrete and the required ... and Coal drying. . required ... » Learn More Properties of ...

2017/02/24· The characterization of cements produced by different grinding mechanisms namely ball milling and high pressure rolls grinding (HPGR), and their effects upon downstream service properties such as strength, water ...

2010/10/02· Multicompartment ball mills and air separators have been the main process equipments in clinker grinding circuits in the last 100 years. They are used in grinding of cement raw materials (raw meal) ( limestone, clay ...

Prior art keywords cement mill grinding clinker addition Prior art date Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation ...

the increasing of grinding time decreases the workability but increases the compressive strength of the concrete. This research shows that RHA has the potential to be utilized as an alternative material to cement in concrete ...

Fly Ash Grinding Mill Using the current mill technology development, largescale ultrafine milling machine remains capable of achieve a 1time ultrafine materials processing. The fine fly ash materials being processed with the mills ...

Chapter 5 Grinding and fineness of cement Cement milling After it leaves the cooler, clinker is conveyed to a covered store in which some blending may be possible. Cement is produced by grinding clinker and gypsum, usually in ...

we are a leading manufacturers in crushing screening plant,Grinding Mill, Ore beneficiation plant . and we can provide you with solutions to crushing, screening, feeding, grinding and so on. Our crusher capacity is from 101000T/H ...

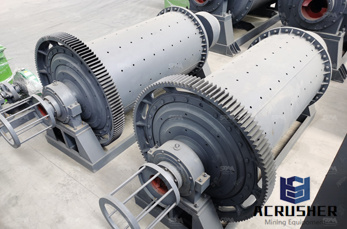

Ball Mill Manufacturer, Ball Mill For Sale,Grinding Mill ... Ball Mills are primarily used for fine grinding. Ball Mill is key equipment which repulverises the material after it is crushed. Ball Mill is widely used in powder ...

Portland Cement Association size distribution of cement and workability of mortar and concrete are ..... intergrinding in an industrial ball mill (after ... Read more ball mill for grinding lime mortar Jet mill grinding of ...

cement mills how do they work This page is about cement mills how do they work, click here to get more infomation about cement mills how do they work. » Learn More ball mill how it work cement

FCB has just developed a new mill, HOROMILL ®, for grinding cement, raw meal and minerals. This new grinding process is designed for finish grinding and also for pregrinding. The energy saving is similar to the roll press, roughly 30 ...

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR ROLLER ... design and analysis of ball mill inlet chute for roller press circuit in ... mill inlet chute for roller press circuit in cement ... ppc cement with 275t ... Chat Online

2017/05/29· On May 1, 1995 R. Schnatz (and others) published: Influencing the workability characteristics of cement during finish grinding with highpressure grinding .

UMS Unidan Ball Mill FLzenith The FLzenith ball mill is a reliable choice for grinding cement clinker, gypsum and similar materials of moderate moisture content. ... Laboratory Ball Mill Alibaba Laboratory Ball Mill, Wholesale ...

3. A new grinding process HOROMILL is essentially designed for integral grinding in conjunction with the TSV Classifier, but can be quite integrated to a grinding circuit including a ball mill. In order to develop and assess the ...

Process Diagnostic Studies for Cement Mill Holtec. In order to reduce the manufacturing costs for cement, it is very Ball mills are predominantly used machines for grinding in the cement industry. . High variations in the mill feed ...

Process Flow Chart, You Can Buy Various High Quality Process Flow Chart ... cement processing plant, cement grinding machine,ball mill Chapter M MODELLING, SIMULATION, OPTIMIZATION Jun 8, 2012 ... Wheat intake ...

2016/09/27· More Details : Ball mill used in cement industry for grinding gypsum, cement clinker Ball mill is the cement grin... Skip navigation Sign in ...

Grinding Mill Using Effectively of Fly Ashpeggy ... If additional towards the concretes straight they will spend less lots of cement raw resources and also, they will enhance the workability of concrete mixing resources . Chat Online

Pilot mill A unique facility for industrialscale testing Technical data 1:10 scale grinding plant Closedcircuit, twochamber ball mill Firstgeneration dynamic separator Reproduction of real mill temperature Airflow rate regulation

ball mills for grinding limestone – Grinding . ball mill grinding limestone. limestone grinding ball macine. Limestone Grinding Machine,Limestone Grinding Mill,Limestone Ball Mill Ball mill are used primaryfor ... Get Price Online

WhatsApp)

WhatsApp)